Aluminum Section Manufacturers in Hyderabad

Raw materials are also supplied for both wholesale and retail markets.

Aluminum has become one of the most sought-after materials in various industries due to its remarkable properties, including lightweight, corrosion resistance, and malleability. Within this framework, aluminum section manufacturers play a crucial role in the supply chain, providing the necessary components that meet the specific requirements of construction, transportation, and various manufacturing sectors. This article delves into the functions, processes, and significance of aluminum section manufacturers in today’s economy.

What Are Aluminum Sections?

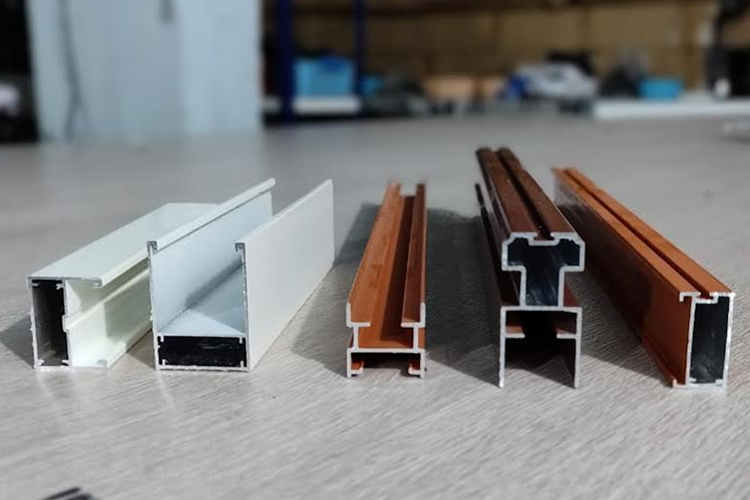

Aluminum sections refer to extruded shapes made from aluminum alloys, designed for specific applications. These sections are produced through a process known as aluminum extrusion, where preheated aluminum billets are forced through a die to create long lengths of profiles with specific cross-sectional shapes like angles, channels, beams, and tubes. The versatility of aluminum sections makes them suitable for a wide range of uses, from building frames and window fixtures to automotive parts and machinery.

The manufacturing of aluminum sections involves several critical steps:

1. Alloy Selection: The first step is selecting the right aluminum alloy, which influences the strength and performance of the final product.

2. Billet Preparation: The aluminum is then heated to a specific temperature, typically between 400°F to 900°F, to make it malleable before extrusion.

3. Extrusion: During this phase, the heated aluminum billet is forced through a shaped die under high pressure. This process shapes the aluminum into the desired profile.

4. Cooling and Aging: Once extruded, the aluminum sections are cooled, often through a water quenching process. Aging may follow to enhance strength and durability.

5. Finishing: The final step includes cutting, machining, surface treatment (like anodizing or painting), and quality testing. These finishing processes ensure that the sections meet the required specifications and standards.

Aluminium Section Manufacturers:

1. Customization: A key strength of aluminum section manufacturers is their ability to produce custom profiles tailored to the needs of different industries. This customization can significantly enhance the functionality and aesthetic appeal of structures and products.

2. Sustainability: Aluminum is 100% recyclable without loss of properties. Manufacturers play a pivotal role in promoting sustainability through recycling initiatives and using recycled aluminum in production, thereby reducing environmental impact.

3. Economic Contribution: The aluminum extrusion industry contributes to the economy by creating jobs, supporting local suppliers, and fostering technological advancements. As industries grow, the demand for high-quality aluminum sections continues to rise.

4. Diverse Applications: From construction materials to automotive and aerospace components, aluminum sections are integral to various sectors. Manufacturers ensure that these sections meet industry-specific standards, enhancing the performance and safety of the final products.

Future Trends in Aluminum Section Manufacturing

- 1. Advanced Extrusion Technologies: Innovations in extrusion techniques, including digital and automated processes, are expected to increase production efficiency and customization capabilities.

- 2. Lightweight Alloys: The demand for lighter materials in automotive and aerospace applications will lead manufacturers to explore and develop advanced alloy compositions.

- 3. Sustainability Initiatives: Sustainability will remain a significant focus, with manufacturers investing in greener processes and increasing the use of recycled aluminum.

- 4. Supply Chain Optimization: Manufacturers will continue to refine their supply chains to mitigate challenges and improve responsiveness to market demands.

Aluminum section manufacturers are vital players in multiple industries, providing essential materials that enhance the performance, sustainability, and innovation of products worldwide. As technology progresses and market demands evolve, these manufacturers will play a crucial role in shaping the future of manufacturing and construction, ultimately contributing to a more sustainable and efficient future. Engaging with reputable aluminum section manufacturers can significantly benefit businesses looking to leverage the unique properties of aluminum for their products.

We proudly offer high-quality Aluminum Section for homes and businesses in Hyderabad, Secunderabad, Shankarpalle, Islampur, Patancheruvu, Miyapur, Madhapur, Manikonda, Gandi Maisamma, Kompally, Alwal, Cherlapalli, Uppal, Dilsukhnagar, Jubilee Hills, Vanasthalipuram, Kokapet, Punjagutta, Banjara Hills, Bachupally, Suraram, Narsingi ensuring you enjoy fresh air without pesky insects.